So yeah, not really, but let me start at the beginning !

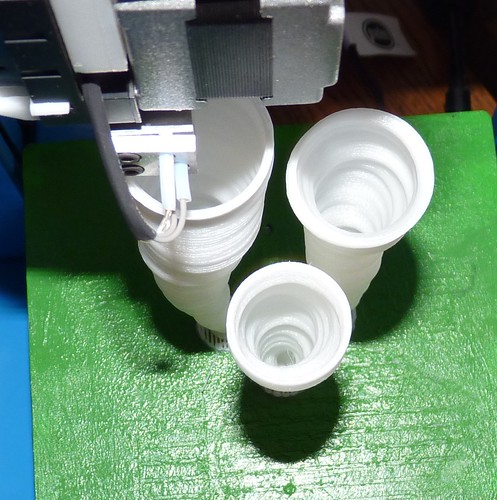

About a year ago, I finally found a satisfactory method to create the things I normally carry around in my head (surrealistic shapes, sculptures, projects and what not) : 3d-printing.

And ever since, I’ve been pondering and researching a DIY 3d-printing concept. Not the usual Makerbot or Reprap stuff (Wonderful projects though! I do hope to get a kit for a Mendel one day, when money flows in instead of out..) But I wish to build one which uses support material, as this allows near-impossible object to be produced.

But a DIY one ? Where to start ?..

Well, luckily I spent a big part of my life taking apart every piece of electronics I could get my hands on, and I figured, using an existing 2d-printer for parts, was a good way to start.

Actually, having cannibalized many ink-jet printers over the years, I think of them more as goody-bags full of usable parts than functional machines 😛 But in this case it’s even better, it’s also a fluid spouting machine.. add some plaster, and we are building already !

I don’t expect to get very fine detail, but that’s ok, because the goals is to go for slightly bigger objects. Say, with a max build volume of cubic A4 (29*21*21 cm^3) . That should suffice for a first attempt?

The search for a usable candidate.

Right, so which printer to use ? What materials ? Would Ink and Plaster really be enough ? Google told me other people on the net did similar projects, but those provide few details and most seem to use what was lying around when they started. And most materials were indeed plaster/sugar and ink. So, it’s do-able ! Yeah 🙂

Explosive ink-diarrhea or “How I fell in love with Epson S21”

But as it happened, I did not have any printers or parts left. And since used ink-jet printers are commonly a case of explosive ink-diarrhea, I started searching for a cheap new one.

That did not take very long, my first sort by price on a price-watch site, led me to the “Epson S21” for only €30,- It has four seperate ink-tanks and a decent resolution.

And more importantly, all chips are hackable (cartridge and ink-waste-pad), there’s also plenty of cheap clone cartridges available, there are even several complete CISS kits (continuous ink supply system).

User experience seemed to be reasonable, but at the time I could find no clear pictures of the inside. Nor any info of other people hacking it. But at a lousy €30,- (did I mention that this included delivery…) I decided, I could not go wrong on this purchase. So.. I ordered it.

It arrived, I tested it and went straight on to dismantle it 😉

I quickly removed all plastic that did not serve any purpose, so I could examine the printer more closely in action. And in the process I think I fell in love with the engineering department at Epson. It’s so wonderfully modular and simple !

The X-axis-print-head assembly looks like a complete usable part, and the Y-axis seems hackable enough.

Very satisfied with this excellent find, I dumped the parts back in the box and started to make some room in the shed before I continued. Because this project will need some permanent space, and it’s bound to get messy, ink.. plaster.. oh yeah >:-)

Springtime, what a joy !

Spring is here, life demands attention, but please check back soon for updates !

Cheers !

Filed under: 3d-printing, DIY, Hacking an Epson S21 by Stijn van der Linden on Sunday, June 6, 2010

Comments Off on My 3D Printer has arrived ! (well.. parts.. sort of..)